Description

The DWL 2000 GS and DWL 4000 GS are industry-leading grayscale laser lithography systems, purpose-built for high-resolution, high-throughput 2.5D pattern generation. Designed for mask and wafer-level lithography, these systems excel in producing complex grayscale microstructures used in MEMS, ICs, micro-optics, microfluidics, holography, and security printing.

Engineered with a professional grayscale mode supporting up to 1023 gray levels, and a write area of up to 400 x 400 mm², these tools are perfect for wafer-level optics for telecommunications and display manufacturing. The integrated GenISys BEAMER software allows for 3D shape optimization, offering optical-quality surfaces with roughness as low as 5 nm.

Key Features & Benefits:

1023 Gray Level Exposure for 2.5D Structures

- Enables creation of complex topographies for micro-lens arrays, holograms, reflectors, and more

- Supports DXF, BMP, STL, X,Y,Z-ASCII file formats

High-Speed & High-Resolution Exposure

- Minimum 500 nm feature size

- Up to 1000 mm²/min grayscale write speed (DWL 4000 GS, Mode V)

Superior Exposure Quality

- Edge roughness: 40 nm

- CD uniformity: 60 nm

- Alignment accuracy: 60 nm

- 2nd layer alignment: 250 nm

Stable ISO 4 Cleanroom Environment

- Integrated temperature-controlled flow box with ±0.1°C stability

Precision Autofocus System

- Real-time optical or air-gauge autofocus

- Compensation range up to 80 µm

Optimized for Micro-Optics & Industrial Production

- Used for wafer-level optics, microfluidics, and high-end holography

- Adopted by multinational corporations in telecom and illumination

Why Choose DWL 2000 GS / DWL 4000 GS?

- Professional grayscale output with minimal surface roughness

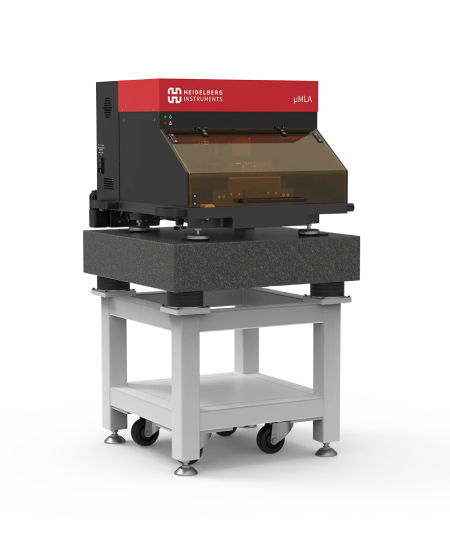

- Robust industrial design with air-bearing stage, fixed optics & real-time monitoring

- Built-in cameras for alignment to existing features

- Powerful layout optimization via GenISys BEAMER software

- ISO 4-compatible chamber ensures process reliability

- Scalable with automation-ready features for high-volume production

Available Modules & System Options:

Write Modes:

- Mode I to V, offering balance between speed and resolution (up to 870 mm²/min for DWL 2000 GS, 1000 mm²/min for DWL 4000 GS)

- Grayscale & binary lithography supported

Exposure Wavelength:

- 405 nm diode laser

Autofocus Options:

- Air-gauge or optical with 80 µm compensation range

GenISys BEAMER Software:

- Advanced 3D proximity effect correction (3D-PEC) and exposure simulation

Automation Add-ons:

- Substrate loading unit

- Additional carrier station

- Pre-aligner and scanner

System Specifications Summary:

| Feature | DWL 2000 GS | DWL 4000 GS |

|---|---|---|

| Max Exposure Area | 200 x 200 mm² | 400 x 400 mm² |

| Write Speeds (Grayscale) | Up to 870 mm²/min | Up to 1000 mm²/min |

| Write Speeds (Binary) | Up to 870 mm²/min | Up to 1000 mm²/min |

| Grayscale Levels | Up to 1023 | Up to 1023 |

| Autofocus | Optical or Air-gauge | Optical or Air-gauge |

| Environment | ISO 4, ±0.1°C stability | ISO 4, ±0.1°C stability |

| Minimum Feature Size | 0.5 µm | 0.5 µm |

| CD Uniformity / Edge Roughness | 60 nm / 40 nm | 60 nm / 40 nm |

| 2nd Layer Alignment | 250 nm | 250 nm |

| System Dimensions | 2350x1650x2100 mm, 3000 kg | Same |

| Electrical Input | 400V ± 5%, 16A | Same |

Click here to view more products from Heildelberg Instruments.

FAQs (Frequently Asked Questions):

Who uses the DWL 2000 GS / 4000 GS systems?

Semiconductor fabs, telecoms, optical labs, and microfluidic developers use it for high-precision 2.5D lithography.

What grayscale applications are supported?

Microlenses, Fresnel lenses, holograms, blazed gratings, reflectors, fluidic channels, and more.

How is the grayscale quality controlled?

Exposure intensity is mapped pixel-by-pixel from 3D CAD input to ensure accurate height control.

Is the system suitable for large-scale industrial production?

Yes! With high write speeds, large exposure areas, and automation options, it’s ideal for volume manufacturing.

What automation options are available?

Substrate loading, pre-alignment, and scanning modules support seamless high-throughput operation.