|

Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

|

AVS 65 Lunch n Learn Complementary XPS TOF-SIMS

For the characterization of polymers and organic-coated surfaces, the combination of two surface sensitive techniques – X-ray Photoelectron Spectroscopy (XPS) and Time-of-Flight Secondary Ion Mass Spectrometry (TOF-SIMS) can be extremely powerful. XPS provides quantitative analysis and short-range bonding chemistry from elements on the outermost surface while TOF-SIMS can provide the molecular information needed to positively identify organic species and the spatial resolution needed to show their lateral distributions on the sample surface. This presentation will discuss the complementary attributes of XPS and TOF-SIMS and demonstrate how combining the two is essential to more fully understand organic surfaces.

We look forward to seeing you there!

Getting “Moore” By Using “Haf” Getting “Moore” By Using “Haf”

Hafnium oxide helps keep microelectronics on the Moore’s law trajectory |

AFM vs. STM: The Resolution Battle The uneasy truce has been broken, as AFM refuses to concede resolution superiority to STM. |

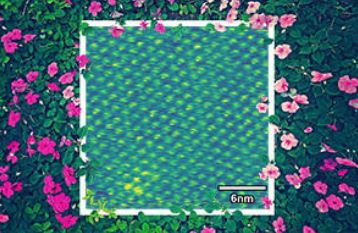

Springtime Beauty at the Nanoscale Just like the brilliant blooms each spring, STM provides a captivating view of the world in which we live. |

|||

What’s Cypher’s High Resolution Secret? You’ve seen Cypher’s high-resolution results, but what makes it possible? Roger Proksch shares the key secret to Cypher’s performance. |

Cypher is a Terrible Earthquake Detector! A man, a dog, and an AFM were sitting in a lab when an earthquake hit. The AFM is the only one that wasn’t startled! |

Springtime Beauty at the Nanoscale Just like the brilliant blooms each spring, STM provides a captivating view of the world in which we live.

|

Herzan is excited to announce it’s Summer Savings Program! This program allows researchers to save big on Herzan’s most popular products (up to 30%), including the TS Series active vibration isolation tables, WaveCatcher site survey tools, and AEK-2002 acoustic enclosures.

We at Herzan are excited to meet with researchers at the Microscopy & Microanalysis Meeting in the Baltimore Convention Center in Baltimore, Maryland. We will be sharing our latest innovations in the field of environmental control, designed specifically to address needs within the microscopy community. Stop by Booth 1206 to learn more about the unprecedented vibration isolation performance of the AVI Series and discover how you can save money and time installing an instrument by utilizing the WaveCatcher site survey tool. Also, there will be some free giveaways at the booth to bring home to family and friends and share with colleagues in the lab!

WHAT: Discover Herzan’s Innovations for Environmental Control Popular ApplicationsHerzan’s environmental solutions support a wide range of research applications relevant to M&M attendees, including:

|

Effective October 1, 2018, Paul Greenwood will be retiring as President of Spectra Research Corporation (SRC). Paul started his career with parent company Alan Crawford Associates in 1982 and has been with SRC since 1993. With SRC, Paul has been responsible for the management of the company as it evolved from a supplier of lasers and optics, to a cross-Canada distributor representing over 15 different companies providing technology for surface science, spectroscopy and materials characterization. We wish Paul well in his retirement.

Serge Dandache will take over as Sales Manager for SRC. Serge, based in Montreal, has been with SRC for 4 years and will maintain his responsibility for direct sales of SRC products in Ottawa, Eastern Ontario, Quebec and Eastern Canada.

Lisa McDonald joins SRC as Account Manager for Central and Western Canada, based out of Toronto. Lisa has many years of experience in instrumentation and chemical distribution including having previously worked with SRC from 2000-2009 as Account Manager.

Contact information for Paul, Lisa and Serge is below. SRC looks forward to helping you with your research instrumentation needs now, and in the future.

| Paul Greenwood paulgreenwood@rogers.com |

Lisa McDonald lisam@aca.ca Tel: 905-502-2031 |

Serge Dandache serged@aca.ca Tel: 514-908-9786 |

About Herzan

Herzan’s mission is to provide carefully articulated environmental solutions for precision research instruments in the fields of Atomic Force Microscopy and Vibration and Acoustic Isolation. The company’s product line encompasses all forms of environmental isolation systems for advanced microscopes and other imaging and analytical instrumentation. They specialize in supporting nanotechnology research but also offer solutions for product testing, in-vitro fertilization and many other applications.

|

McGill University AFM Summer School and Workshop

• Video-Rate AFM with the Asylum Research Cypher VRS Hands-on demonstration labs will complement the lectures. It’s an excellent opportunity to get tips and tricks on AFM operation, and to see video-rate AFM in action. Speakers Registration Serge Dandache Spectra Research Corporation Phone 905-890-0555 Toll Free : 1-866-753-4433 |

B&W TEK QTRamTMPowered by B&W Tek’s award-winning STRaman™ technology, the QTRam features a portable Raman system with 21 CFR Part 11 compliant software on an embedded tablet computer for blend & content uniformity, quantitative analysis, and at-line analysis for process monitoring & final release testing. About B&W TEK

B&W Tek is an advanced instrumentation company producing optical spectroscopy and laser instrumentation, as well as laboratory, portable and handheld Raman systems. We provide spectroscopy and laser solutions for the pharmaceutical, biomedical, physical, chemical, LED lighting and research communities. Originally established as a producer of green lasers in 1997, we’ve grown into an industry-leading, total solutions provider; coupling our core technologies with custom design and manufacturing capabilities.

|

For a 2nd year material science researchers from around the globe will gather for an innovative online experience where we will explore the latest cutting edge analytical solutions used to enable the development of new and advanced materials. Watch presentations from leading materials scientists, access hundreds of technical papers and videos, and ask questions live – all without leaving your desk! When you register you’ll be able to:

When: May 16, and you’ll be able to revisit content through 2018

|

781-249-2828 Agenda

ContactTim Walsh, to schedule time in the Open Lab Drew Griffin, Asylum Research. |