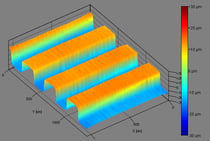

Information on mechanical properties is important in many applications. AM-FM Viscoelastic Mapping Mode lets you quickly and gently image viscoelastic properties including storage modulus and loss tangent with nanoscale spatial resolution. Its very wide operating range, from less than 1 MPa to hundreds of GPa, makes it a highly versatile technique. AM-FM Mode is available on all MFP-3D™ and Cypher™ family AFMs and is one of many options in Asylum’s NanomechPro™ Toolkit for nanomechanical measurements.

Capabilities and Benefits

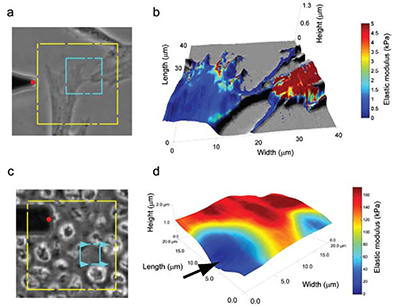

Asylum’s exclusive AM-FM Viscoelastic Mapping Mode1 is a flexible, convenient tool for nanomechanical characterization. With a range of applicability that spans a remarkable six orders of magnitude in storage modulus (from less than 1 MPa to hundreds of GPa), it is a general-purpose technique for anything from biomaterials and polymers to metals and ceramics. AM-FM Mode provides elastic information including storage modulus, Young’s modulus, and contact stiffness and viscoelastic information including viscoelastic loss tangent and loss modulus. AM-FM Mode gets results by operating at two cantilever resonances simultaneously. As the name indicates, the first resonance is used for tapping mode imaging, also known as amplitude modulation (AM), while a higher resonance mode is operated in frequency modulation (FM). At resonance, the cantilever frequency and phase respond sensitively to changes in sample properties. Small frequency and phase shifts can be measured with very high precision and accuracy, reducing uncertainty and increasing sensitivity. You can use raw output signals to quickly visualize relative contrast and identify sample components; or you can use the observed amplitude, phase, and frequency data to make quantitative estimates of mechanical properties based on built-in or your own models.

Because AM-FM Mode works like tapping mode in the repulsive regime, it is familiar and straightforward to use. It also has the other advantages of tapping mode including fast scanning, high spatial resolution, and gentle forces. On high speed, low-noise systems such as Asylum’s Cypher S and ES AFMs, modulus mapping in AM-FM Mode can routinely operate at line scan rates as fast as 20 Hz (equivalent tip velocity 300 μm/s) and forces as low as 50 pN.2 Low forces mean less sample deformation, typically only a few nanometers, which both minimizes damage and maximizes spatial resolution. Because the FM amplitude is just a tiny fraction of the AM amplitude and is at a different frequency, topographic imaging operates the same as in standard tapping mode. This makes AM-FM Mode very stable and reliable to operate.

Complex fluid/fluid systems can be characterized with interfacial rheology

Complex fluid/fluid systems, such as emulsions, gels and various surfactant solutions, are the basis of most of our everyday consumer products from detergents to healthcare, but also found in biology and industrial processes such as in enhanced oil recovery and mineral processing.

Complex fluid/fluid systems can be characterized with interfacial rheology

Complex fluid/fluid systems, such as emulsions, gels and various surfactant solutions, are the basis of most of our everyday consumer products from detergents to healthcare, but also found in biology and industrial processes such as in enhanced oil recovery and mineral processing.

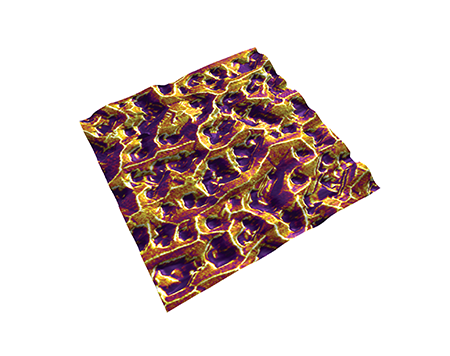

Evaluate the influence of surface roughness on wettability

While contact angle (CA) goniometry involving placing a drop of liquid on a surface and measuring the resulting angle has been around for many years, we have only recently developed a system to account for the underlying surface’s micro-scale roughness.

Evaluate the influence of surface roughness on wettability

While contact angle (CA) goniometry involving placing a drop of liquid on a surface and measuring the resulting angle has been around for many years, we have only recently developed a system to account for the underlying surface’s micro-scale roughness.

Wettability analysis for inkjet printing

Surface tension of inkjet inks and the wettability of the printing substrate are important factors influencing the final printing quality and process reliability. Surface tension and interfacial interactions can be explored with various technologies.

Wettability analysis for inkjet printing

Surface tension of inkjet inks and the wettability of the printing substrate are important factors influencing the final printing quality and process reliability. Surface tension and interfacial interactions can be explored with various technologies.

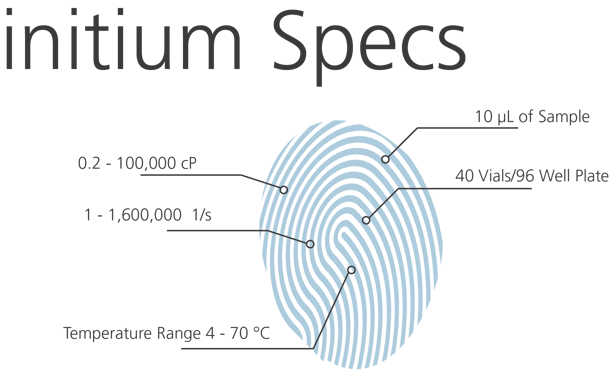

microVISC™ Viscometer

microVISC™ Viscometer