Topological structures in multiferroic materials have recently received considerable attention because of their potential use as nanoscale functional elements. Their reduced size in conjunction with exotic arrangement of the ferroic order parameter and potential order parameter coupling allows for emergent and unexplored phenomena in condensed matter and functional materials systems. This will lead to exciting new fundamental discoveries as well as application concepts that exploit their response to external stimuli such as mechanical strain, electric and magnetic fields. In this review we capture the current development of this rapidly moving field with specific emphasis on key achievements that have cast light on how such topological structures in multiferroic materials systems can be exploited for use in complex oxide nanoelectronics and spintronics.

- Introduction

Topological defects play important roles in nature. They are found in fields as diverse as cosmology, [ 1] particle physics, superfluidity, liquid crystals, and metallurgy, manifesting themselves as e.g. screw/edge-dislocations in liquid crystals, [ 2] magnetic flux tubes in superconductors, [ 3] and vortices in superfl uids [ 4] etc. The theory of topological defects, as applicable to condensed matter physics, dates back to the seminal work of Mermin in 1979. [ 5] In a non-uniform ordered medium (i.e., media that can be described by a function f( r ) which assigns an order parameter to every point in that space), topological defects are those regions including points, lines and surfaces where the order parameter ceases to vary continuously, forming regions of lower dimensionality.

At the same time, the possible values that the order parameter can take constitute the order parameter space. For example, the order parameter space for planar spins can be taken as a unit vector that can point in any direction in a plane, i.e., the space is a circle. This allows for mapping of a closed contour of the order …….. Read More from PDF

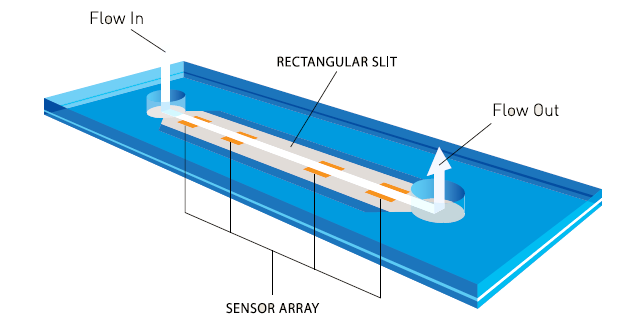

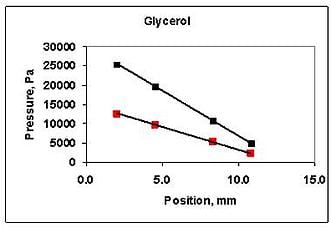

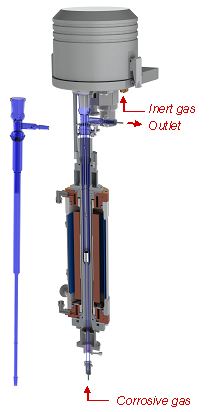

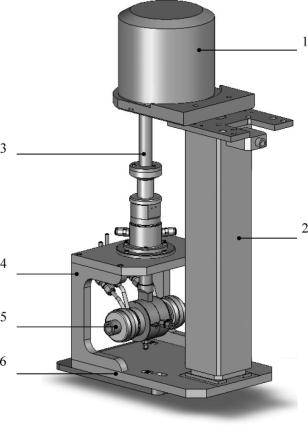

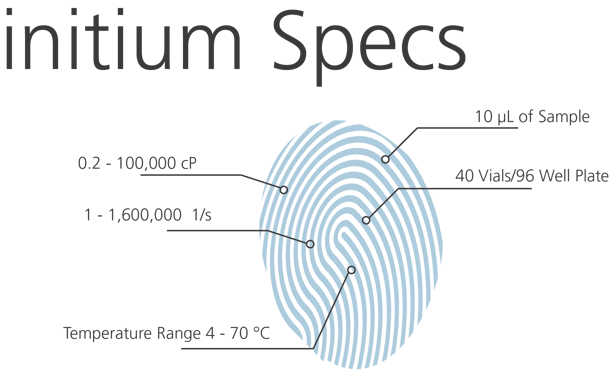

microVISC™ Viscometer

microVISC™ Viscometer