SRC will be exhibiting here

Microscopical Society of Canada

Welcome to the website for the MSC 43rd Annual Meeting. The annual meeting will take place in Edmonton on June 7-10, 2016, at theUniversity of Alberta.

The information needed to register for the 43rd Annual Meeting, on how to prepare and submit manuscripts for oral or poster presentation along with the scientific program will be posted soon.

The official flyer of the 2016 meeting is now available. Please feel free to post it in your University, Institute or Enterprise.

Until then, please feel free to contact us if you have any questions.

WITec will be exhibiting hereUpcoming ConferencesAPRIL 7, 2016

CIC/SCI Canada Seminar and Awards Dinner

Toronto, ON, CA

|

SRC will be exhibiting hereResearch DayThe Departments of Chemical Engineering at Ecole Polytechnique de Montreal and McGill University invite you to our annual Winter Research Day! Chemical Engineering Research Day Tuesday, March 15th, 2016, 8:30AM – 6PM McGill University New Residence Hall, 3625 Av du Parc, Montréal, QC H2X 3P8 Prince Arthur Ballroom (Level C) Keynote Speaker

Program Research Day Program [.pdf] Registration and Abstract Submission (CLICK HERE): SponsorsWe gratefully acknowledge contributions from our industry partners and collaborators, without whom this event would not be possible.

|

||

McGill AFM Summer School – Sponsored by Spectra Research and Asylum Research – May 12-13.Until then, please feel free to Contact Us! if you have any questions. |

CANADA’S PREMIER SOURCE FOR SCIENTIFIC INSTRUMENTS

Spectra Research Corporation (SRC), the foremost Canadian supplier of scientific instruments to governments, universities and commercial facilities.

Save time searching for the scientific equipment you need from leading international brands—it’s all here, under one roof.

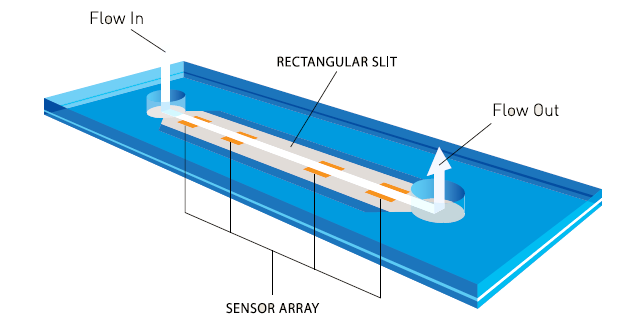

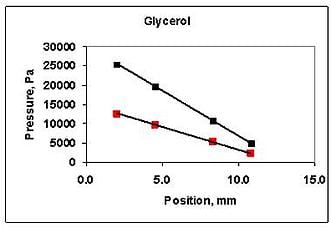

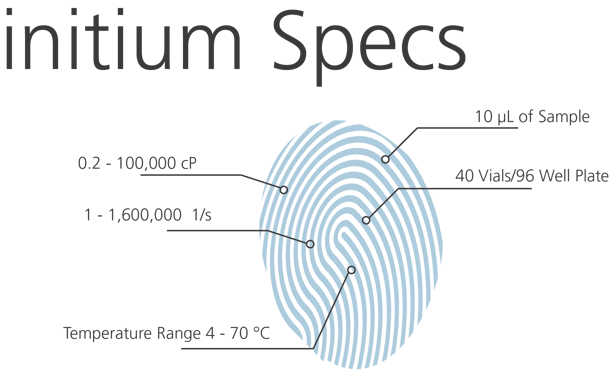

microVISC™ Viscometer

microVISC™ Viscometer