Oxford Instruments Asylum Research Presents the Webinar “How to Choose the Right Probe for Your Atomic Force Microscopy Experiments”

Target audience: All AFM users

Keywords: Atomic Force Microscopy (AFM), Scanning Probe Microscopy (SPM), probes, cantilever

August 24, 2016 (Santa Barbara, CA) Successful atomic force microscopy (AFM) imaging starts with choosing the right probe for your sample and scan mode. It’s one of the most important considerations when doing an experiment. Asylum Research’s webinar “How to Choose the Right Probe for Your AFM Experiments” aims to make all AFM users experts at probe selection. The webinar will be presented September 8, 2016, 8:00am PDT, by Asylum Research Applications Scientist, Dr. Ted Limpoco. Registration is at www.oxford-instruments.com/ProbeWebinar.

“Choosing the right probe from hundreds available, even for an experienced user, can be a daunting task,” said Dr. Limpoco. “At Asylum, we scan an incredible number of different samples under various conditions and modes daily, so we have a deep understanding of what works and what doesn’t. This is an excellent opportunity to share our knowledge and experience with the entire AFM community.”

Topics discussed in the webinar include:

• AFM probe fundamentals and calibration

• Probe selection for imaging in air and liquid

• Probe selection for specific scan modes (e.g. MFM, high resolution imaging, nanomechanics)

• Specialized probes

• Real-world image examples

About Oxford Instruments Asylum Research

Oxford Instruments Asylum Research is the technology leader in atomic force microscopy for both materials and bioscience research. Asylum Research AFMs are widely used by both academic and industrial researchers for characterizing samples from diverse fields spanning material science, polymers, thin films, energy research, and biophysics.

In addition to routine imaging of sample topography and roughness, Asylum Research AFMs also offer unmatched resolution and quantitative measurement capability for nanoelectrical, nanomechanical and electromechanical characterization.

Recent advances have made these measurements far simpler and more automated for increased consistency and productivity. Its Cypher™ and MFP-3D™ AFM product lines span a wide range of performance and budgets. Asylum Research also offers its exclusive SurfRider™ AFM probes among a comprehensive selection of AFM probes, accessories, and consumables. Sales, applications and service offices are located in the United States, Germany, United Kingdom, Japan, France, India, China and Taiwan, with distributor offices in other global regions.

About Oxford Instruments plc

Oxford Instruments designs, supplies and supports high-technology tools and systems with a focus on research and industrial applications. Innovation has been the driving force behind Oxford Instruments’ growth and success for over 50 years, and its strategy is to effect the successful commercialisation of these ideas by bringing them to market in a timely and customer-focused fashion.

The first technology business to be spun out from Oxford University, Oxford Instruments objective is to be the leading provider of new generation tools and systems for the research and industrial sectors with a focus on nanotechnology. Its key market sectors include nano-fabrication and nano-materials. The company’s strategy is to expand the business into the life sciences arena, where nanotechnology and biotechnology intersect.

This involves the combination of core technologies in areas such as low temperature, high magnetic field and ultra high vacuum environments; Nuclear Magnetic Resonance; x-ray, electron, laser and optical based metrology; atomic force microscopy; optical imaging; advanced growth, deposition and etching.

Oxford Instruments aims to pursue responsible development and deeper understanding of our world through science and technology. Its products, expertise, and ideas address global issues such as energy, environment, security and health.

For further information please Contact Us

SRC will be Exhibiting at NanoOntario

SRC will be Exhibiting at NanoOntario

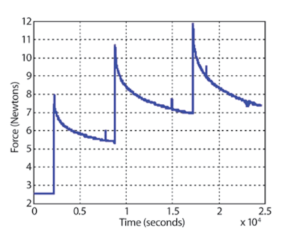

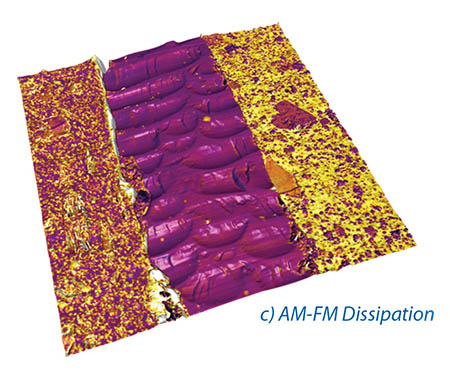

variety of industrially, biologically and structurally important materials. An Atomic Force Microscope (AFM) tip interacting with a sample experiences forces originating from many different sources – elasticity, viscosity, adhesion, van der Waals – to name a few. Hence, it has become increasingly clear that reliable and accurate materials properties measurements require looking at your sample in more than one way. Single techniques are simply insufficient for accurately and rigorously revealing sample properties and can often yield misleading and even inaccurate results and conclusions.

variety of industrially, biologically and structurally important materials. An Atomic Force Microscope (AFM) tip interacting with a sample experiences forces originating from many different sources – elasticity, viscosity, adhesion, van der Waals – to name a few. Hence, it has become increasingly clear that reliable and accurate materials properties measurements require looking at your sample in more than one way. Single techniques are simply insufficient for accurately and rigorously revealing sample properties and can often yield misleading and even inaccurate results and conclusions.