Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

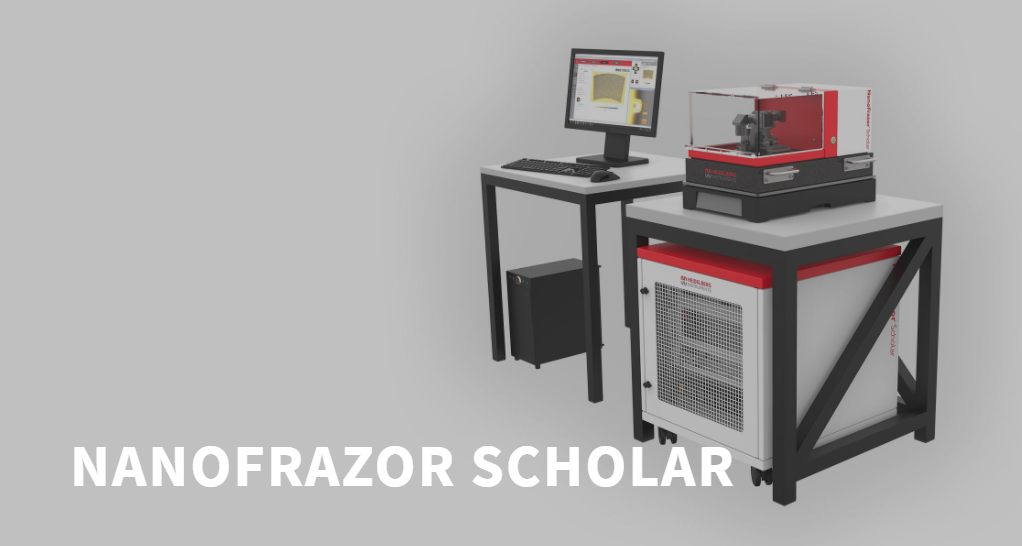

Heidelberg Instruments NanoFrazor Scholar

TABLETOP DIRECT WRITE NANOLITHOGRAPHY & AFM

- Detection of features buried under resist.

- Fast exchange and calibration

- Integrated topography sensor

- Entry-level nanopatterning system with many unique capabilities

- Thermal probe lithography is the fastest of all scanning probe lithography methods

- Direct resist removal and in-situ inspection enable fast turnaround times.

- Well-suited for academic research groups as a simple tool to easily create their own high-quality nanopatterns and devices

Introducing the Heidelberg Instruments NanoFrazor Scholar

Heidelberg NanoFrazor Scholar is particularly suitable for academic research groups requiring an affordable system for nanofabrication. NanoFrazor Scholar is used for nanopatterning of quantum devices on 1D/2D materials such as quantum dots, Dolan bridges and Josephson junctions, and nanoscale arrays. Its unique capabilities enable new devices in new materials. For example, it is used for advanced applications such as grayscale photonics devices, nanofluidics structures or biomimetic substrates for cell growth; local modification of materials by heat, e.g. chemical reactions and physical phase changes.

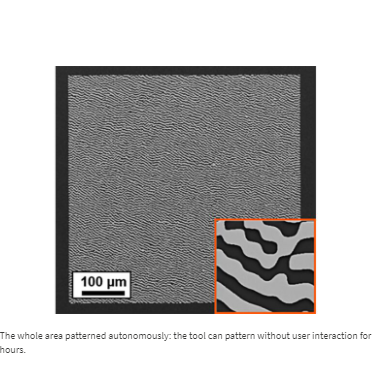

In-situ imaging enables two unique features: markerless overlay, and comparison of the written and target patterns during writing so the parameters can be immediately adjusted. This approach, called closed-loop lithography, results in sub-2 nm vertical precision for 2.5D (grayscale) shapes of any complexity. Fast and precise control of a heated nanoscale tip enables innovation not otherwise feasible.

Key Features

NANOSCALE MATERIAL CONVERSION.

The heated tip can alternatively be used to induce highly localized modification of materials: Deprotection of functional groups, precursor conversion, amorphization, crystallization, change of magnetic orientation, etc.

OTHER UNIQUE CAPABILITIES

- 3D grayscale lithography with unprecedented accuracy enabled by closed-loop lithography

- Accurate overlay and stitching without artificial markers, achieved by in-situ AFM

Key Benefits

The technology behind the system is the result of more than 20 years of intensive research and development (R&D) that started at IBM Research Zürich and now takes place at Heidelberg Instruments Nano. The NanoFrazor hardware and software are constantly advancing to extend the capabilities and performance of the tool and its range of applications. Our dedicated team of experts continues to develop and optimize the pattern transfer processes for different applications. We compile this know-how in a growing library of best practices and protocols to support our customers.

Trust the Experts at Spectra Research Corporation

Spectra Research Corporation (SRC) offers a range of innovative high-quality scientific products and laboratory services to industrial and scientific markets throughout Canada.

Specifications

| Writing performance | |

|---|---|

| Minimum structure size [nm] | 20 |

| Minimum lines and spaces [half pitch, nm] | 30 |

| Grayscale / 3D-resolution (step size in PPA) [nm] | 3 |

| Writing field size [X μm x Y μm] | 50 x 50 |

| Field stitching accuracy (markerless, using in-situ AFM imaging) [nm] | 50 |

| Overlay accuracy (markerless, using in-situ AFM imaging) [nm] | 50 |

| Write speed (typical scan speed) [mm/s] | 0.5 |

| Write speed (50 nm pixel) [μm²/min] | 500 |

| AFM imaging performance | |

| Lateral imaging resolution (feature size) [nm] | 10 |

| Vertical resolution (topography sensitivity) [nm] | 0.2 |

| Imaging speed (@ 50 nm resolution) [μm²/min] | 500 |

| System features | |

|---|---|

| Substrate sizes | 1 x 1 mm² to 50 x 50 mm², 0 – 20 mm thickness (100 x 100 mm² possible with limitations) |

| Optical microscope | 3.6 μm optical resolution, 1.5 mm x 1.1 mm field of view |

| Magnetic cantilever holder | Fast (< 1 min) and accurate tip exchange |

| Housing | Compact housing with separate controller rack, active vibration isolation (small footprint) or passive vibration isolation (slightly better performance) included. |

| Software features | GDS and bitmap import, AFM image analysis and drawing for overlay, fully automated calibration routines, Python scripting |

| NanoFrazor cantilever features | |

| Integrated components | Tip heater, topography sensor, electrostatic actuation |

| Tip geometry | Conical tip with < 10 nm radius and 750 nm length |

| Tip heater temperature range | e 25 °C – 1100 °C (< 1 K setpoint resolution) |

| System dimensions & installation requirements | |

| Height × width × depth | 50 cm x 32 cm x 30 cm |

| Weight | 100 kg |

| Power input | 1 x 110 or 220 V AC, 10 A |

| Gas input | Compressed air (> 4 bar) for passive vibration isolation |

| Vibration and noise level | Ambient acoustic noise levels need to be kept below 40 dB for best performance. A strong table is required if the active vibration isolation is chosen. Floor requires vibration level VC-B. |

| Other considerations | |

| Recipe book with detailed descriptions of various processes is included (regularly updated with software). | |

| Cantilever tips degrade over time (> 50 h patterning possible). Exchange is fast and low cost for tool owners. | |

| A cleanroom or special laboratory is not required. No vacuum needed. | |

| Unique capabilities make it easy to receive government funding (for system itself or later research projects) |