Description

Achieve exceptional precision in thin-film coating applications with the Mini E-Beam Evaporator – EVAP Series by Nikalyte. Designed for research labs and production facilities, this compact UHV-compatible evaporator uses a finely controlled electron beam to directly heat crucibles, enabling efficient deposition of high-purity metals such as Gold, Silver, and Chrome.

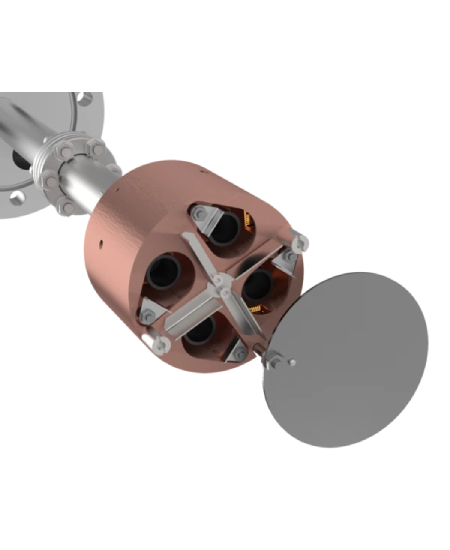

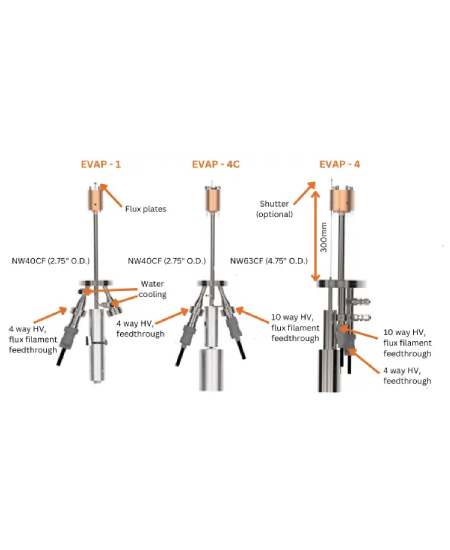

Available in three configurations—Single Pocket (EVAP-1), Compact 4-Pocket (EVAP-4C), and High-Capacity 4-Pocket (EVAP-4)—this system enables co-evaporation of up to 4 materials, making it ideal for lift-off processes, contact metallization, and precise nanofabrication on heat-sensitive substrates.

By utilizing partial beam collimation and flux monitoring, the EVAP series ensures superior material utilization and reduced thermal impact, offering a major advantage over traditional e-beam hearth or thermal boat evaporators.

Features of Mini E-Beam Evaporators:

High-Precision Metal Deposition

- Direct electron beam heating of crucibles or rods

- Ideal for Au, Ag, Cr, and other metals

- Controlled evaporation with minimal substrate heating

Multi-Pocket Co-Evaporation

- EVAP-4 and EVAP-4C models support simultaneous 4-material evaporation

- Manual or pneumatic independent shutter control

Compact & UHV Compatible

- Mounts via NW40CF or NW63CF flange

- Bakeable up to 250°C

- Fully UHV compatible with minimal outgassing

Advanced Flux Monitoring

- Built-in ion flux plate measures deposition rate in real time

- Flux regulation, filament, and power control via combined 4-channel controller

Customizable & Efficient

- In-vacuum length customizable (standard 300 mm)

- Cooling flow: minimum 1.0 l/min

- Active copper cooling reduces heat radiation

Why You Should Buy:

- Minimizes waste of expensive materials like gold and platinum

- Compact footprint perfect for limited-space UHV chambers

- Fast setup and swap with replaceable crucibles and liners

- Superior for low-temperature thin-film deposition on delicate substrates

- Scalable for complex coating requirements using multi-pocket co-evaporation

Technical Specifications Summary:

| Model | EVAP-1 | EVAP-4C | EVAP-4 |

|---|---|---|---|

| Mount Flange | NW40CF (2.75″) | NW40CF (2.75″) | NW63CF (4.5″) |

| No. of Pockets | 1 | 4 | 4 |

| Co-Evaporation | No | Yes | Yes |

| Crucible Sizes | 210, 390, 1000 mm³ | 210, 390 mm³ | 210, 390, 1000 mm³ |

| Crucible Materials | Mo, VC, W | Mo, VC, W | Mo, VC, W |

| Crucible Liners | PBN, Al₂O₃ | PBN, Al₂O₃ | PBN, Al₂O₃ |

| Bakeable Temp | Up to 250°C | Up to 250°C | Up to 250°C |

| Flux Monitoring | Yes | Yes | Yes |

| Shutter Control | Manual/Pneumatic | Manual/Pneumatic | Manual/Pneumatic |

| Power Supply | Combined 4-channel | Combined 4-channel | Combined 4-channel |

| In-vacuum Length | 300 mm (customizable) | 300 mm (customizable) | 300 mm (customizable) |

Click Here to view similar products from Nikalyte.

FAQs (Frequently Asked Questions):

Q: Can the EVAP system be integrated into an existing UHV system?

A: Yes! The EVAP series is fully UHV-compatible and can be integrated with custom or commercial vacuum chambers.

Q: What’s the thermal impact on substrates?

A: The evaporator is designed to have minimal heat load due to efficient heat absorption and active cooling, making it ideal for sensitive substrates.

Q: Is it possible to monitor deposition rates in real time?

A: Absolutely. Each unit comes with flux monitoring via ion flux plates, ensuring precise rate control.

Q: What materials are supported?

A: Common process metals like Gold (Au), Silver (Ag), Chrome (Cr) and more using crucible or rod feedstock.

Q: How is co-evaporation managed?

A: The EVAP-4 and 4C models include 4 independent crucible pockets, each controllable via the included 4-channel power supply.