Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

Nanosurf Customizing

AFM systems fully tailored to your specifications

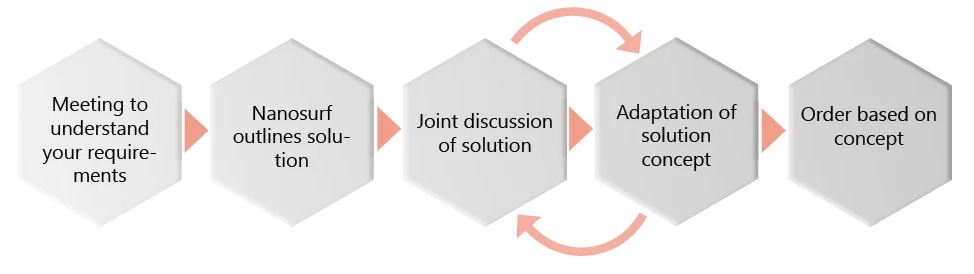

- Meeting to understan your requirements

- Nansosurf outlines solution

- joint discussion of solution,

- adaptation solution concept

- order based on concept

Introducing the Nanosurf Customizing

About our customizing process

As atomic force microscopes continue to enter more and more areas of applications, especially in industry, production processes and quality control, standard AFM systems are often not suitable for the task at hand. For these cases, when you need the AFM to be fully integrated in a process, or your samples are too large for standard setups, Nanosurf offers the unique service of designing and developing custom AFM systems and stages that will allow you to perform your measurements with minimal disruption of your established process.

Key Features

Curved surface

| Automated XZΘ translation stage | |

| Max. traverse path XZ/Θ | 250/60 mm / 100° |

| Sample size | max. Ø380 mm x 220 mm |

| Stage size | 450 mm x 550 mm x 460 mm |

| Noise level | <0.5Å |

AFM measurements on large concave or convex samples require the scan head to rotate such that the cantilever approaches the surface under the same angle on every location. Economic full 360° manual rotation of the sample platform and motorized

XZΘ-travel ensures to reach every point on the sample.

Handling

This micrometer transfer stage allows the examination of a sample with an inverted optical microscope, where the sample faces down, and with AFM, where the sample faces up. The sample – a glass lens – is fixed in place after the area of interest is located using the optical microscope and then flipped over and transferred to the AFM with a repositioning accuracy of better than 10µm.

Levelling

| Automated XYZΘΦ translation and goniometer stage | |

| Max. traverse path XYZ/ΘΦ | 72/46/5 mm / ±5° |

| Sample platform size | 75 mm x 50 mm |

| Sample size | max. 75 mm x 50 mm x 13 mm |

Precision alignment stage: two goniometer stages and three highly sensitive force sensors were incorporated to allow automated levelling of a sample plane with respect to the scan head within 0.005°. Humidity control and a custom built cantilever holder were developed to facilitate nano-imprint lithography. LEE, I.-Ning, et al. Large-area scanning probe nanolithography facilitated by automated alignment and its application to substrate fabrication for cell culture studies. JoVE (Journal of Visualized Experiments), 2018, Nr. 136, S. e56967. WANG, Shuai, et al. Large-area scanning probe nanolithography facilitated by automated alignment of probe arrays. RSC Advances, 2015, 5. Jg., Nr. 75, S. 61402-61409.

Key Benefits

Sometimes custom adaptations make the difference

Do you need to perform AFM measurements, but your samples are large, require special handling or your experiments go beyond established techniques and methods? We take your needs seriously and will jointly work with you on a solution. In close cooperation and in continuous dialog with you, our instrument development team will design and construct a system tailored to your exact needs. Contact us with a first description of your needs and we‘ll be happy to get back to you to discuss your project in depth.

Trust the Experts at Spectra Research Corporation

Spectra Research Corporation (SRC) offers a range of innovative high-quality scientific products and laboratory services to industrial and scientific markets throughout Canada.

Specifications

System workflow and specifications

| Flex-ANA system workflow | |

|---|---|

| Mounting and calibrating the cantilever |

|

| Sample loading and overview image |

|

| Definition of measurement locations and conditions |

|

| Start of the automated measurement |

|

| Analysis optimization |

|

| Results | Export of final histograms and maps |

| (1)Accessible modulus range depends on choice of cantilever | |

| MTS 32 specifications | |

|---|---|

| Range (X / Y / Z) | 32 / 32 / 5 mm |

| Optional σZ range | 100 µm |

| Positioning accuracy (X / Y / Z / σZ) | <1 / <1 / <1 / <0.001 µm |

| Repositioning accuracy (X / Y / Z) | <2 µm |

Datasheet