Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

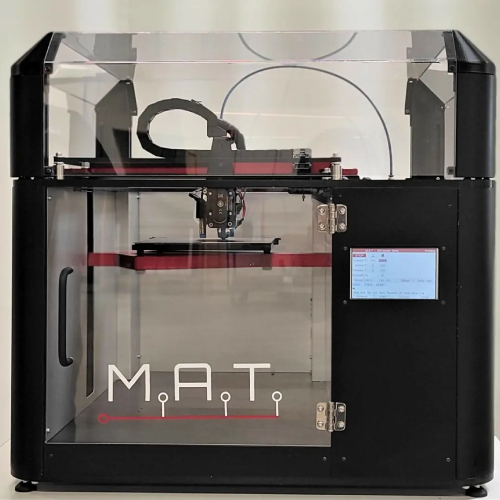

Thermo Scientific – Energy 11 Twin-Screw Extruder for Battery R&D

The Energy 11 Twin-Screw Extruder can be set up for a wide range of applications encountered in current battery R&D. The fully ported, horizontally split barrel allows for flexible feeding of solid and liquid ingredients. Interchangeable die designs adapt to a range of materials from dry granules, polymeric solid-state electrolytes, and electrode films to wet slurries. Eight precisely controlled temperature zones along the barrel ensure flexibility in processing.

Introducing the Thermo Scientific – Energy 11 Twin-Screw Extruder for Battery R&D

The Energy 11 Twin-Screw Extruder is highly versatile and suits a broad spectrum of applications in current battery R&D. Its fully ported and horizontally split barrel facilitates the flexible feeding of both solid and liquid ingredients. You can adapt it to various materials, including dry granules, polymeric solid-state electrolytes, electrode films, and wet slurries. With eight precisely controlled temperature zones along the barrel, it offers unparalleled processing flexibility.

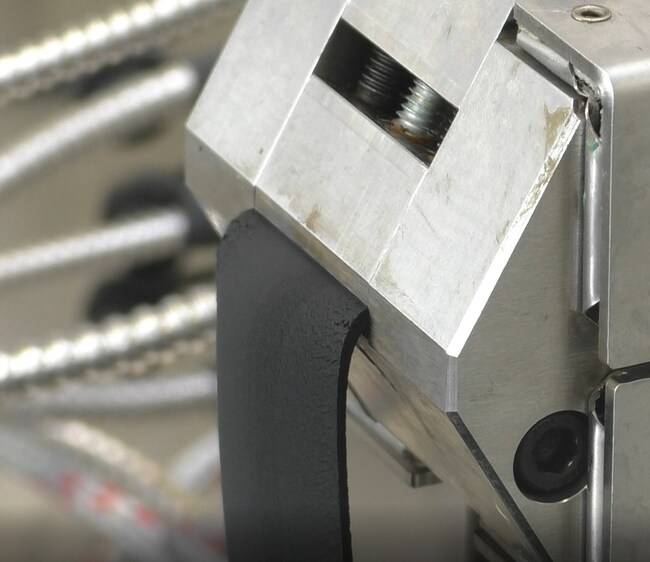

This extruder’s unique shear force capability significantly reduces solvent usage during mixing, typically decreasing it from 60% to just 15%. This reduction not only cuts solvent costs but also promises substantial energy savings during subsequent drying processes.

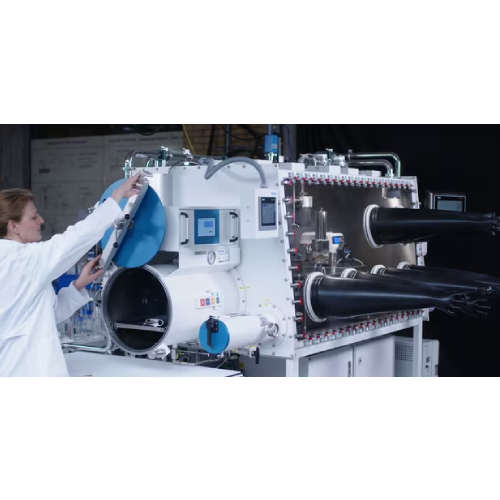

Due to its wide range of accessories, the Energy 11 PROTECT integrated glovebox solution allows users to develop and produce cathode and anode slurries as well as electrolytes for solid-state batteries. Its high dispersive and distributive mixing capabilities also make possible the processing of dry electrodes under an argon atmosphere.

All extruder product contact parts can be disassembled completely and quickly for easy and thorough cleaning and to prevent cross contaminations. Rapid changes to experiment conditions are enabled by this feature as well.

Whatever your material requirements are, a range of feeding options for solid and liquid materials, all controlled by the extruder’s control panel, make sure that all ingredients go into the process precisely. Being a continuous process by design, the mixing done by the Energy 11 extruder eliminates batch-to-batch variations and always delivers a thoroughly homogenous final product.

APPLICATIONS

• All solid-state battery material mixing

• Handling of pure lithium anodes

• Separator film extrusion

• Lithium-ion electrode slurry mixing

• Solvent-reduced mixing and dry cathode processing

Key Features

- Thorough Mixing: The Energy 11 Twin-Screw Extruder enables continuous and thorough mixing for battery processing.

- Versatile Setup: Its fully ported, horizontally split barrel and interchangeable die designs accommodate a wide range of materials and applications.

- Temperature Control: Eight precisely controlled temperature zones along the barrel ensure flexibility in processing.

- Flexible Feeding: The design allows for flexible feeding of solid and liquid ingredients.

- Shear Force Capability: High shear force capability significantly reduces solvent usage during mixing.

- Detachable Control Panel: The extruder can be operated in a fume hood or glovebox when needed.

- Material Compatibility: Product contact parts are made from CPM® steel, reducing the risk of metal abrasion.

- Easy Disassembly: The assembly of the feed port, barrel, screw, and die can be detached with one tri-clamp connection for fast cleaning and cross-contamination prevention.

- Optional Accessories: Various optional accessories and application packages expand its functionality.

- Safeguards: Easy removal of product contact parts and individual replacement options reduce the risk of cross-contamination.

- Superior Slurry Quality: Achieve a finer distribution of all ingredients, ensuring consistent and high-quality slurry.

- Direct Scalability: The extruder’s geometry allows for direct scalability to larger extruders for production processes.

Key Benefits

- Enhanced Mixing Efficiency: Achieve thorough and continuous mixing for battery processing, ensuring consistent and high-quality results.

- Versatile Application: Adapt the Energy 11 Twin-Screw Extruder to a wide range of battery research and development applications, from dry granules to wet slurries.

- Efficient Solvent Reduction: Significantly reduce solvent usage during mixing, leading to cost savings and reduced energy consumption during drying processes.

- Flexible Configuration: The fully ported, horizontally split barrel and interchangeable die designs provide flexibility in feeding and material compatibility.

- Easy Maintenance: Detachable control panel and parts made from CPM® steel enable easy cleaning and minimize the risk of cross-contamination.

- Diverse Application Options: Optional accessories expand its capabilities, allowing for processes such as electrode material mixing and solvent-free cathode production.

- Cross-Contamination Safeguards: Easily remove product contact parts for cleaning, with individual replacement options available.

- Consistent Slurry Quality: Ensure a homogenous slurry for battery materials, eliminating batch-to-batch variations.

- Scalable for Manufacturing: The extruder’s scalability makes it suitable for both research and production processes.

Trust the Experts at Spectra Research Corporation

Spectra Research Corporation (SRC) offers a range of innovative high-quality scientific products and laboratory services to industrial and scientific markets throughout Canada.