Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

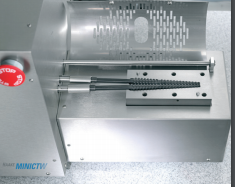

Thermo Scientific HAAKE™ MiniCTW Micro-Conical Twin Screw Compounder

- Throughput range 0.4 kg/h to 20 kg/h (material dependent)

- Segmented screw design and removable top half barrel

- A screw length adjustment kit enables small quantity compounding

- A fully ported barrel allows maximum flexibility for feeding and degassing

- Contact parts selectable from three steel grades

- An easy-to-operate touch screen with integrated feeder control

- Broad accessory portfolio, e.g.. dies, feeders, water bath, conveyor belt, strand or die face pelletizers, haul off, and spooler

- The granulation kit enables customers to switch between melt extrusion and wet/melt granulation

- Geometrically scalable screw and barrel design across portfolio

Introducing the Thermo Scientific HAAKE™ MiniCTW Micro-Conical Twin Screw Compounder

HAAKE MiniCTW Micro-Conical Twin Screw Compounder for industrial research and development needs a sample amount of 5g or 7cm3 only. Nobody can afford to waste expensive raw materials when developing new products. In addition, it helps to shorten time-to-market and cut development costs to gain a distinct competitive advantage. Therefore, quick and early assessments of a new material are key. The micro-conical twin screw compounder Thermo Scientific HAAKE MiniCTW allows extrudating as little as five grams of material and thereby helps to accelerate the conception of the final product.

Key Features

The HAAKE MiniCTW Micro-Conical Twin Screw Compounder is ideal for the precisely controlled reactive extrusion of high-viscous melts that is being done via an MS-Windows™based software that offers several test set-ups. By running the instrument in circulation mode, the required reaction time for the reactive mixture can be controlled easily. At the end of the test, the bypass valve can be opened and the sample is extruded as a strand. By measuring the torque of the drive motor, the reaction process can be monitored effectively. Test results are stored in the software. The HAAKE MiniCTW Micro-Conical Twin Screw Compounder is one model within our suite of micro-conical twin screw compounders that serves a variety of markets, including polymer, bioscience, nanotechnology and pharmaceutical. The instrument differs from the well-established Thermo Scientific HAAKE MiniLab micro-compounder in that it is designed specifically for industrial research and development whereas the HAAKE MiniLab is focused on polymer development applications. To complete our comprehensive solutions, our international team of material characterization experts provides proven answers for small sample compounding

Key Benefits

When compounding expensive or small scale materials such as nano-composites or engineered polymers, you need a fast, dependable, cost efficient method to obtain tangible results.

Priced right, the HAAKE Mini CTW Micro-Conical Twin Screw Compounder is the answer: The HAAKE MiniCTW requires as little as five grams or seven milliliters (ml) of material for compounding, which is especially beneficial for industries that compound expensive or small-scale materials such as nano-composites, bio-polymers or pharmaceuticals. By using the optional force feeder, customers can continuously extrude very small material volumes. The instrument is based on proven, conical twin screw technology with co- and counter-rotating screws, and it works as a standalone unit with data export. Due to the channel and a backflow bypass valve, the residence time can be exactly defined.

Recommended for:

This miniaturized, high-tech tool is perfect for in industrial research in material science in the following markets:

- Automotive

- Aerospace

- Electronics

- Polymer Processing

- Polymer Screening

- Colorants

- Specialty inks / Toners

- Building and Construction

- Consumer Products

- Pulp and Paper

Trust the Experts at Spectra Research Corporation

Spectra Research Corporation (SRC) offers a range of innovative high-quality scientific products and laboratory services to industrial and scientific markets throughout Canada.

Specifications

| Max. Speed | 300 min-1 |

|---|---|

| Speed Range | 1 to 360 min-1 |

| Barrel and Screws | High performance plastic mold steel (M340) |

| Hertz | 50/60Hz |

| Voltage | 230V ± 10%, 115V ± 10% |

| Control Mode | Constant Speed, Constant Torque |

| Volume (Metric) | 7mL |

| Material | Stainless steel 1.4122 Cr coated |

| Compounders | Yes |

| Description | HAAKE MiniCTW; Manual valve |

| Max. Temperature | 300°C |

| Extruder Design | Conical co–/counter rotating |

| Max. Torque | 5Nm/screw |

| Feeder Information | Manual feeding, Force feeder (optional) |

| Micro Compounding | Yes |

| Heating Time | 80 to 240°C |

| Motor Power | 400w |

| Unit Size | Each |

| Catalog number | Unit Size | Description | Max. Speed | Max. Temperature | Max. Torque | |

|---|---|---|---|---|---|---|

| 567-2090 | Each | HAAKE MiniCTW; Manual valve | 300 min-1 | 300°C | 5Nm/screw |