Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

Genizer

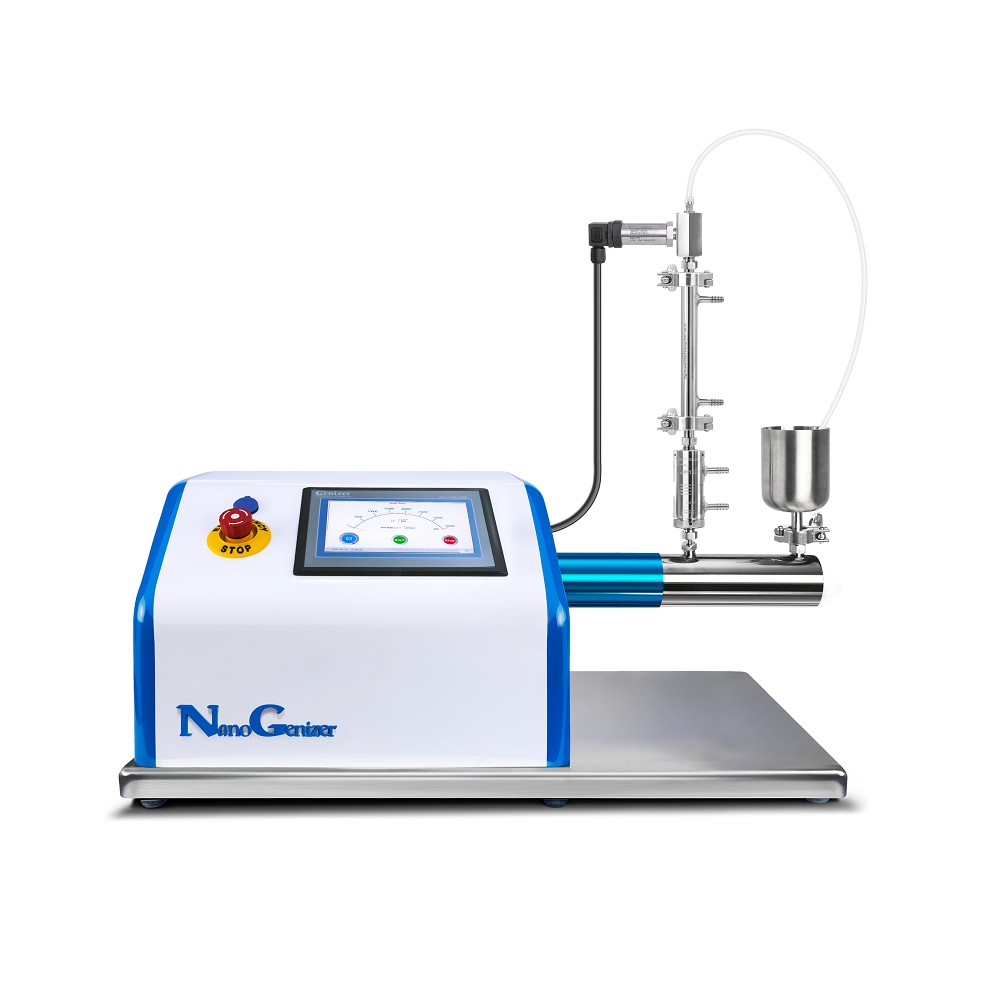

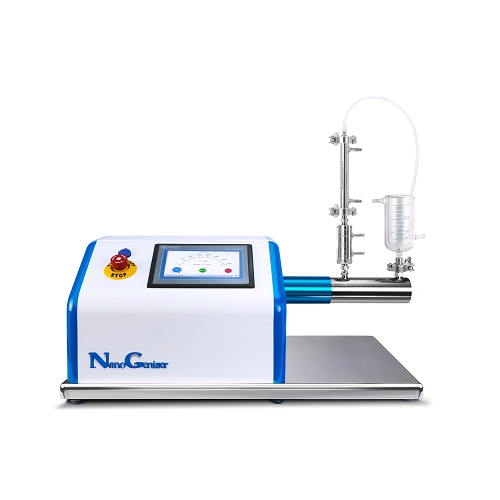

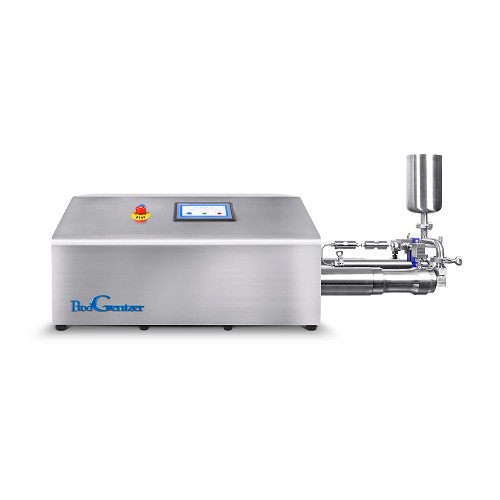

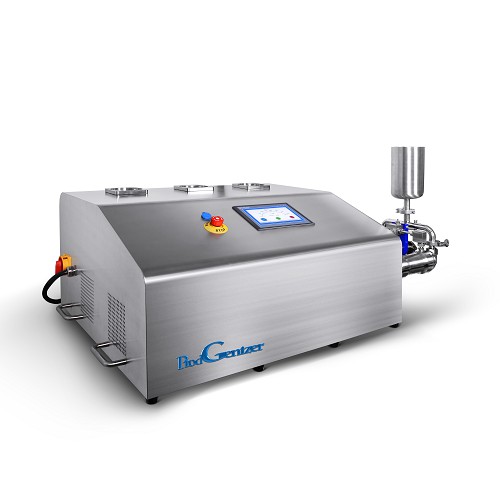

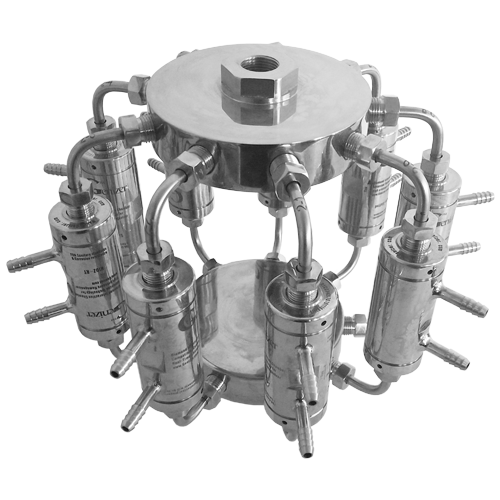

Genizer, located in Technology Link in Greater Los Angeles/CA/USA, is dedicated to advancing homogenizer nanotechnology. We provide high pressure homogenizers, liposome extruders, sanitary heat exchangers, diamond interaction chambers, and high pressure gauges compatible with other brands of high pressure homogenizers and high pressure pumps. Equipment produced ranging form very small batch testing through to scale up in manufacturing.