Discount Products: Look through products available for a 25% – 50% discount in 2020. The items provided on a first come, first serve basis. View Discounted Products

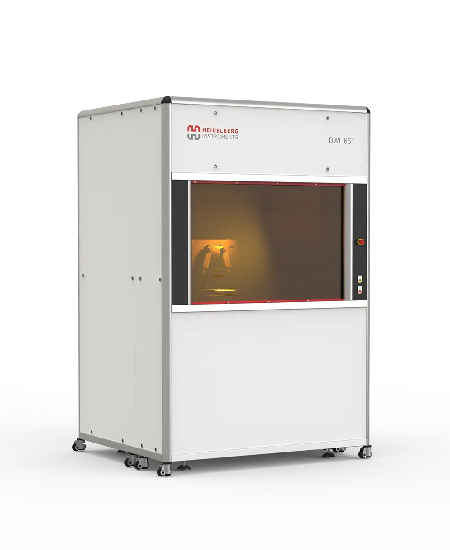

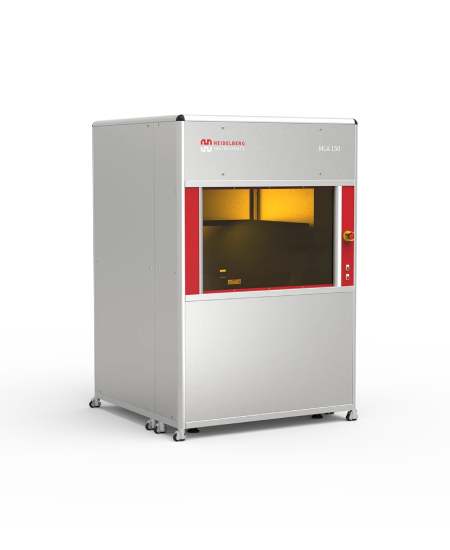

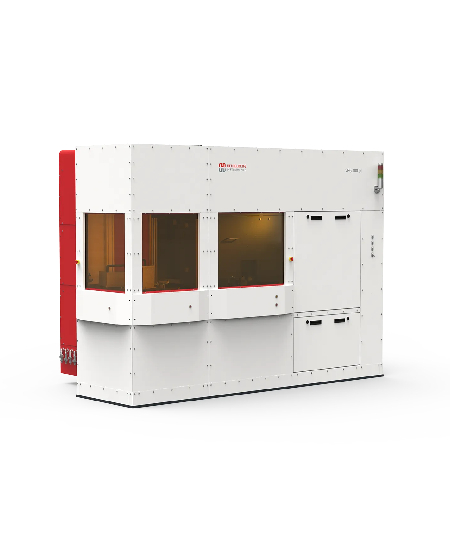

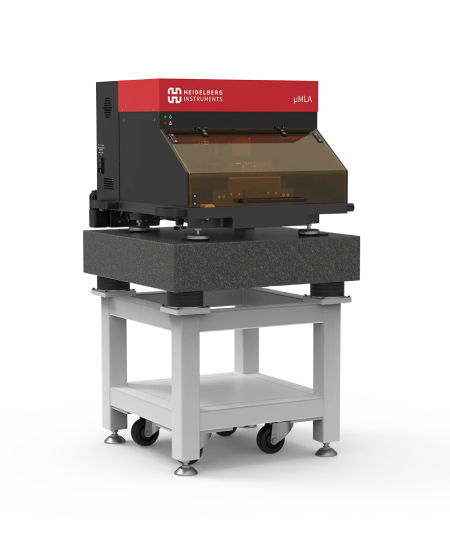

Heidelberg Instruments

Heidelberg Instruments is dedicated to producing leading-edge solutions for micro- and nanofabrication which meet the specific Direct Write Lithography requirements of our customers, with whom we form long-lasting partnerships by helping them deliver specific applications for today and for the world of tomorrow, while also supporting system solutions throughout their product lifetimes.

To remain at the forefront of our industry, we continuously expand our vast knowledge in micro- and nanofabrication and work hard to advance our specialized engineering skills in mechanics, electronics, optics and software development. This combined unique expertise enables us to develop exclusive solutions that outperform conventional lithography machinery and empower our customers.

At Heidelberg Instruments, we are committed to constantly redefining the limits of laser lithography and exploring new methods of micro- and nanotechnology.